Storage Technology for Large Liquefied Ammonia Tank

Liquefied Ammonia, which is expected to expand as a transport medium (carrier) of hydrogen in recent years, can also contribute to the reduction of carbon emissions through its mixed combustion in Japan domestic coal-fired power plants. Based on our track record of delivering liquefied Ammonia tanks overseas, we will also contribute to the Japan domestic expansion of liquefied Ammonia usage.

Features of Liquefied Ammonia

| Contents | Liquefaction Temperature | Density (Liquid) |

Liquefaction Volumetric Shrinkage |

Remarks |

|---|---|---|---|---|

| Liquefied Propane Liquefied Butane |

-45℃ -10℃ |

580 kg/m3 601 kg/m3 |

1/250 1/300 |

--- |

| Liquefied Ammonia | -33℃ | 680 kg/m3 | 1/800 | Toxic. Induces stress corrosion cracking in steel. |

Our Initiatives for Liquefied Ammonia

- We have a track record of delivering the products to Middle East, North Africa, and East Asia.

- We have delivered more than 100 LPG (Liquefied Petroleum Gas) tanks with similar liquefaction temperatures to Ammonia in Japan and overseas.

- We participate in the Clean Fuels Ammonia Association (CFAA)/Ammonia Storage Tank Standards Review Working Group and contributed to the development of technical standards.

Development of Large Liquefied Hydrogen Tank

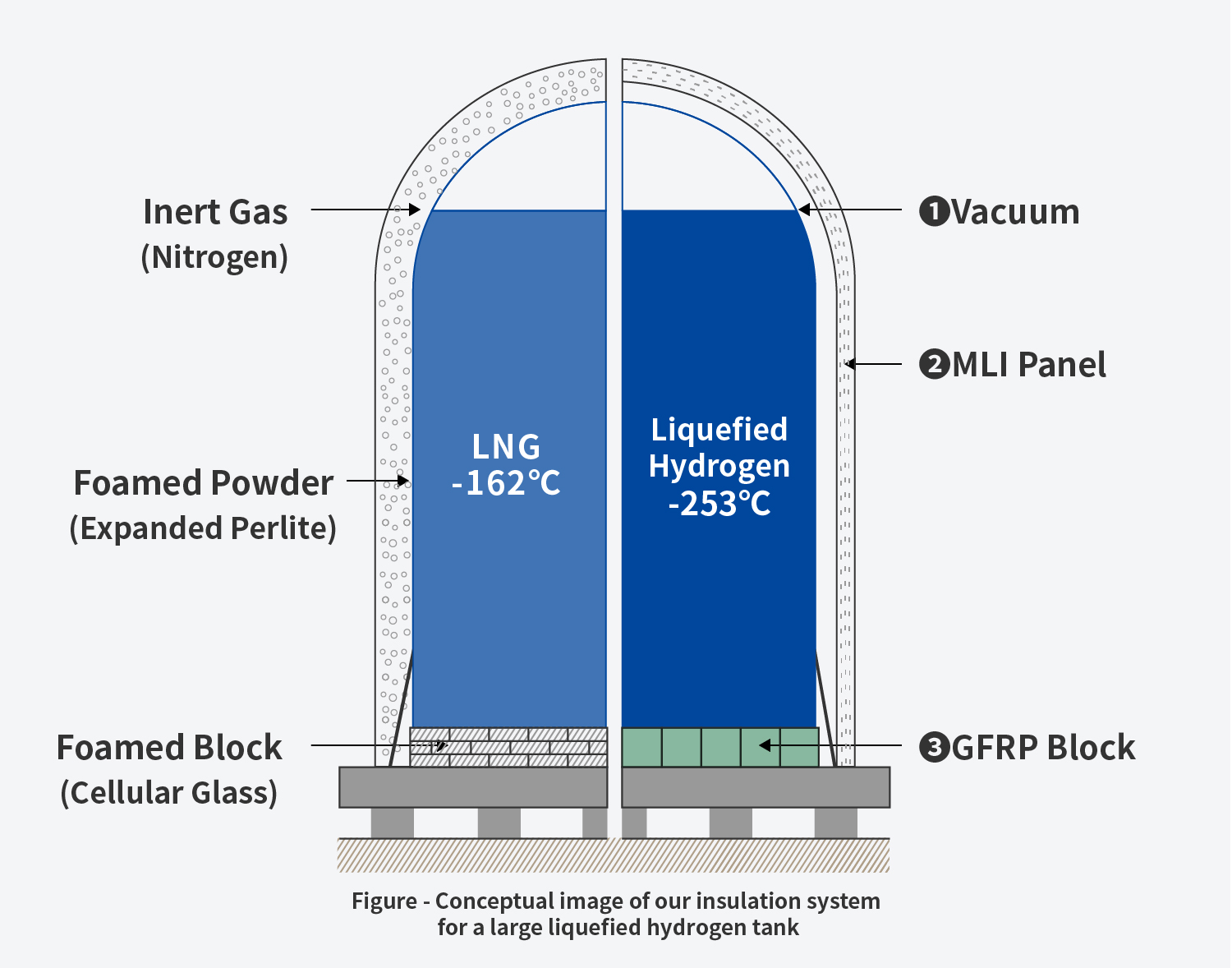

TKK is aiming to construct the world's first large-scale liquefied hydrogen tank of 50,000 m3 for the commercialization of hydrogen power generation around 2030. Liquefied hydrogen has a lower liquefaction temperature and evaporates more easily than LNG. Considering this, TKK is conducting research and development on the thermal insulation system of hydrogen tanks, which is different from conventional LNG tanks.

Technical Study of a Large Liquefied CO2 Tank

Utilizing our design and construction technologies of cryogenic tank and pressure vessel, we have successfully completed the technical study of a large liquefied CO2 tank with low temperature and low pressure specifications using 9% nickel steel.

1. Background

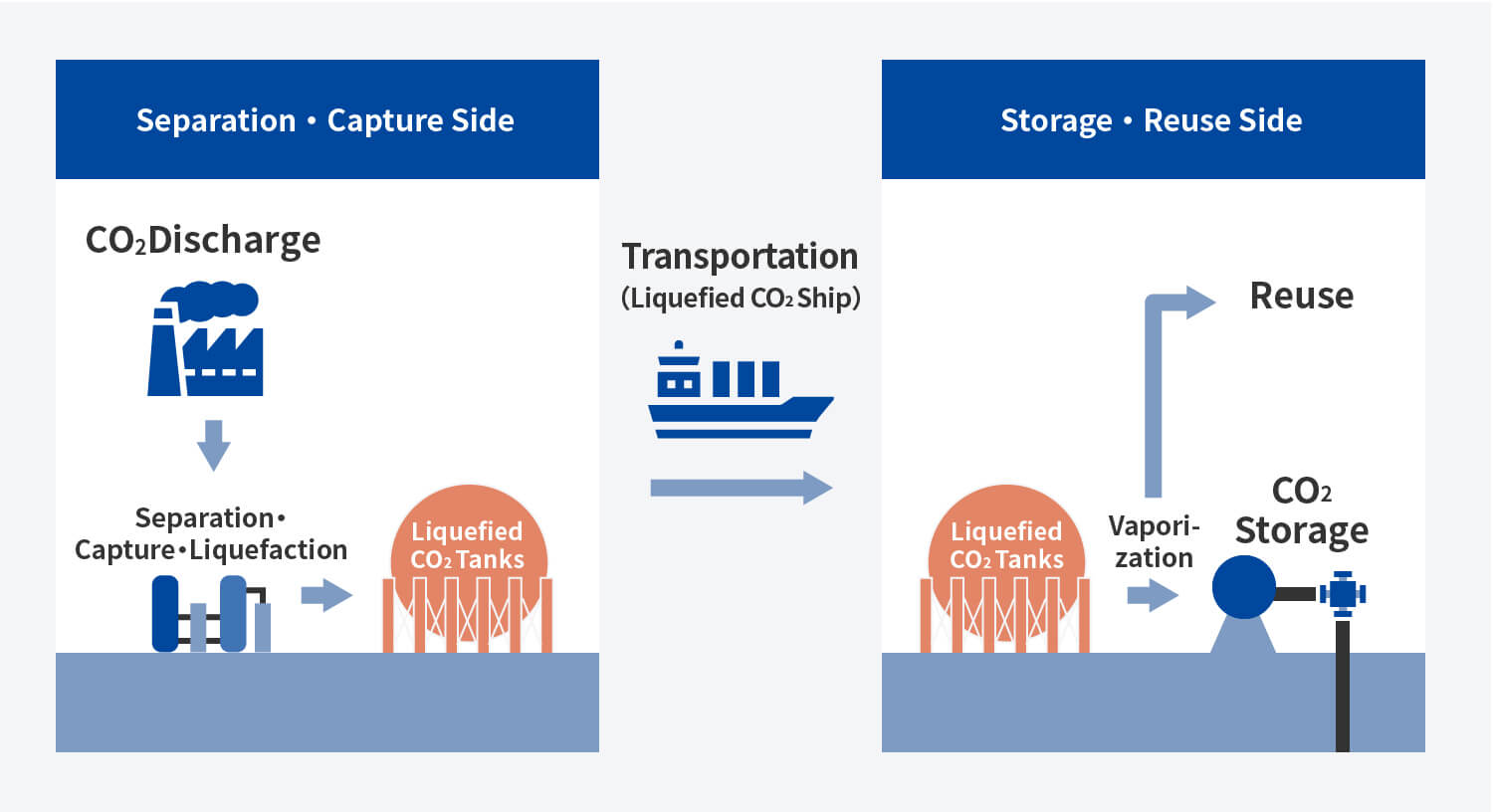

In order to achieve carbon neutrality, there are global expectations for the expanded use of CCS/CCUS*1 technology. Large liquefied CO2 tanks are important as they facilitate the storage function of separated and captured CO2 at both export and import terminals. On the other hand, it is difficult to increase the storage capacity of existing medium-temperature, medium-pressure tanks made of high-tensile steel. Hence, low-temperature, low-pressure tanks will be essential for future mass transportation by ship.

- ※1

CCS: Technology to separate and capture CO2 and store it underground (Carbon Dioxide Capture and Storage)

CCUS: Technology to utilize the captured CO2 in addition to its storage (Carbon Dioxide Capture, Utilization and Storage)

2. Outline of Large Liquefied CO2 Tank

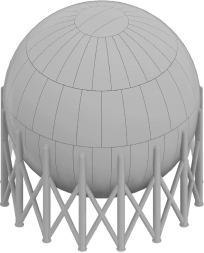

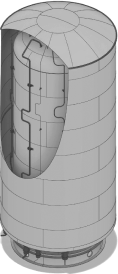

| Spherical Tank | Double Shell Vertical Tank | |

|---|---|---|

| Main Material | 9%Nickel Steel | |

| Capacity | Over 10,000 tons | Over 5,000 tons |

| Characteristic | Allows for maximum storage capacity | Effective utilization of storage area and Superiority of maintainability |

| Shape |  |

|

Large LNG (liquefied natural gas) Tank Track Record

Since receiving the first order for LNG (Liquefied Natural Gas) tanks for Brunei in 1969, TKK has delivered many LNG tanks, mainly to LNG import terminals of electric power and gas companies in Japan and to LNG export terminals in natural gas producing countries overseas. In addition, we constructed the world's largest 230,000 KL tank, the first tank in the world to use 7% nickel-TMCP (Thermo-Mechanical Rolling Process) steel, which has the same strength and toughness as 9% nickel steel but uses approximately 20% less nickel, which is an expensive rare metal.