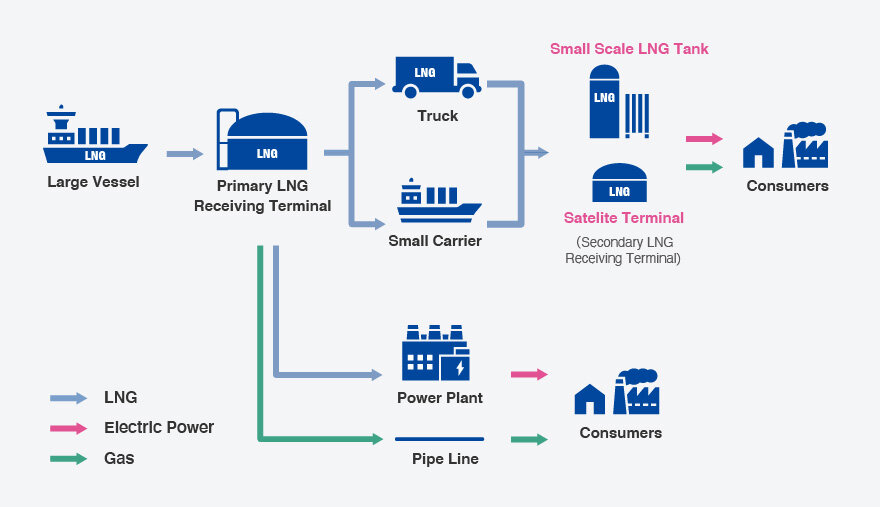

Small Scale LNG Tank for Satellite Terminals

Satellite Terminal is equipped with smaller scale LNG storage tank and auxiliary facilities. TKK supports ever-growing LNG distribution business by supplying small-scale LNG tank based on our unparalleled experience and expertise as an international leading company in the industry.

Tank System

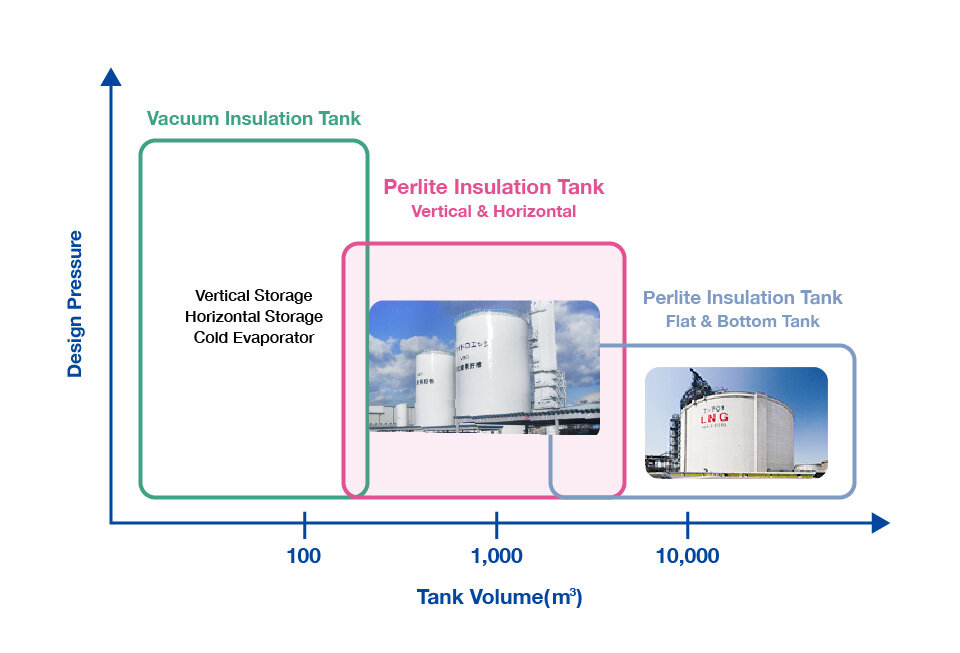

Above-ground LNG Tank Application

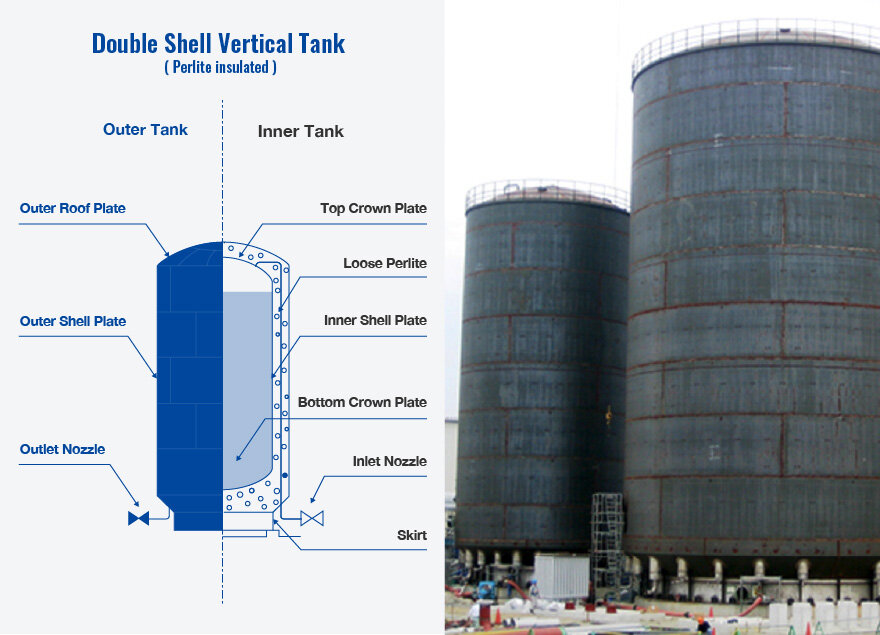

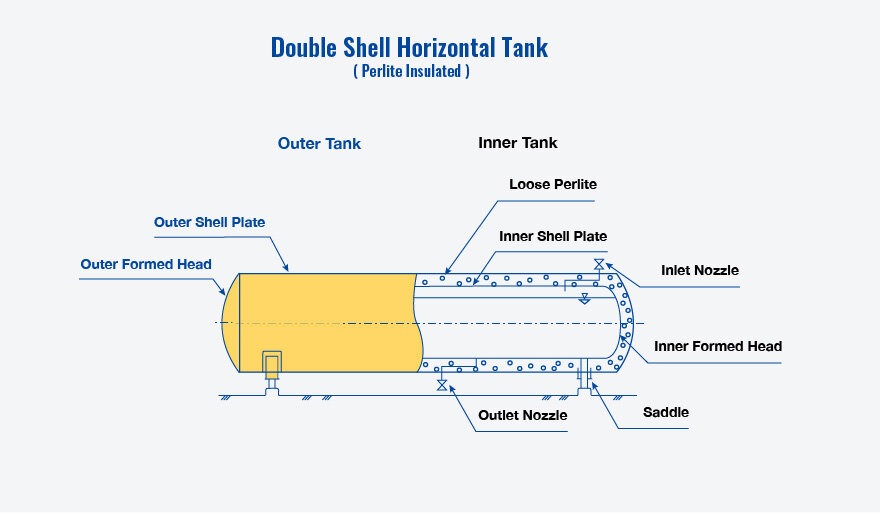

Structure

- This storage unit consists of an inner tank made of cryogenic steel and an outer tank of normal steel.

- The space between the two tanks is insulated with loose perlite.

Service

- This storage unit is designed to store content at cryogenic temperature:

LNG (-162 degree C) and liquefied industrial gases, LO2 (-183 degree C), LN2 (-196 degree C), etc.

Advantages

Double Shell Vertical Tank has the following advantages over Flat Bottomed Cylindrical Double Shell Storage Tank.

- Capable of higher design pressure. Thus, the tank can be operated up to 1.0 MPa without discharging BOG* or requiring a compressor.

- Tank can be delivered in a shorter time period and at a lower cost.

- Upright design of vertical tank enables land-saving layout.

* BOG: Boil Off Gas

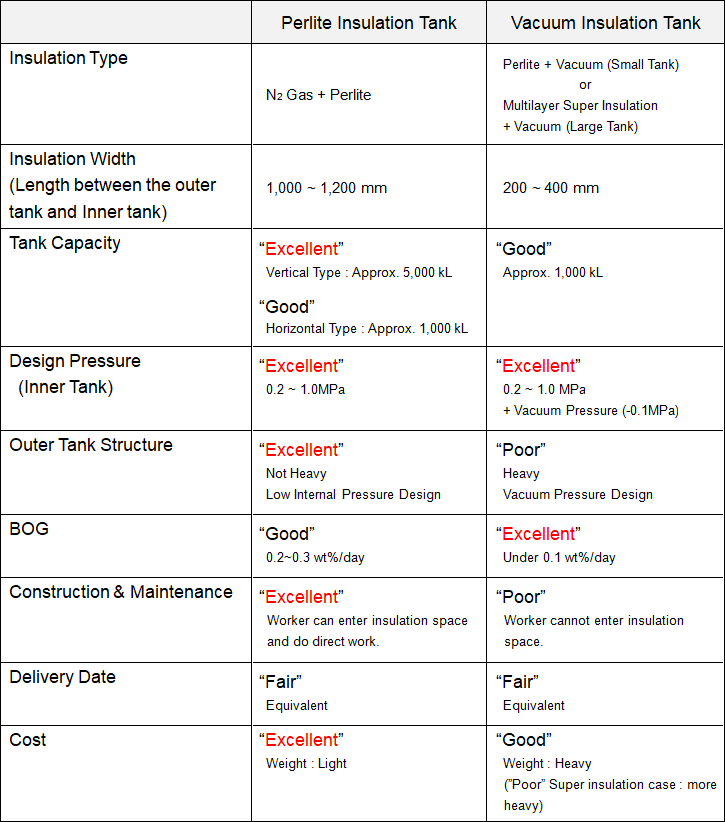

Perlite Insulation Tank vs Vacuum Insulation Tank

-

Note) *1

The Difference of inner tank weight by changing design pressure

a) For 1.0 MPa design pressure case Inner tank of perlite insulation tank is lighter 10% than vacuum insulation tank.

b) For 0.3 MPa design pressure case Inner tank of perlite insulation tank is lighter 30% than vacuum insulation tank.

TKK's Approach to Double Shell Vertical Tank & Horizontal Tank

Site Fabrication Method & Offsite Fabrication Method

Site Fabrication Method

- Site fabrication method is TKK's specialty as we have extensive experience as a tank builder to fabricate large capacity tanks on site.

Offsite Fabrication Method

- Offsite fabrication method is recommended in case of a shorter time window for site construction. Offsite fabrication can be carried out without waiting for the completion of other site activities, such as site preparation, piling and foundation work. The small-scale LNG tank can be fully fabricated at our fabrication shop and transported to the site on customer’s demand.

Design Standardization

- TKK provides the standardized small-scale LNG tank line-up;. Our standardized tank design satisfies the prevailing international Codes and Standards. Standardized design helps to reduce both delivery period and the product cost.

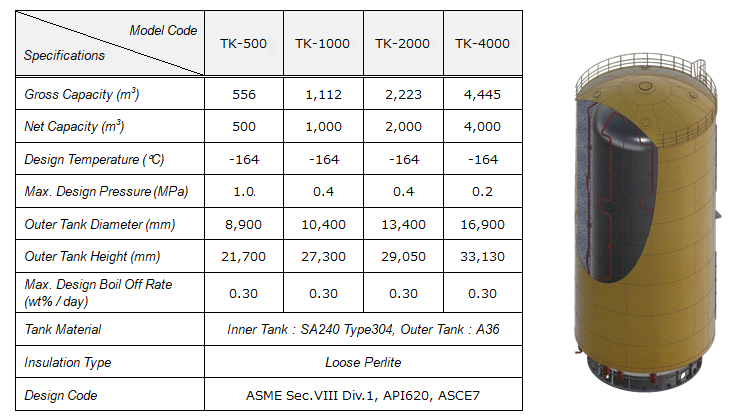

Line-up of Standardized Vertical Tanks

We can also respond to made-to-order demands with a capacity range from 300 to 5,000 m3.

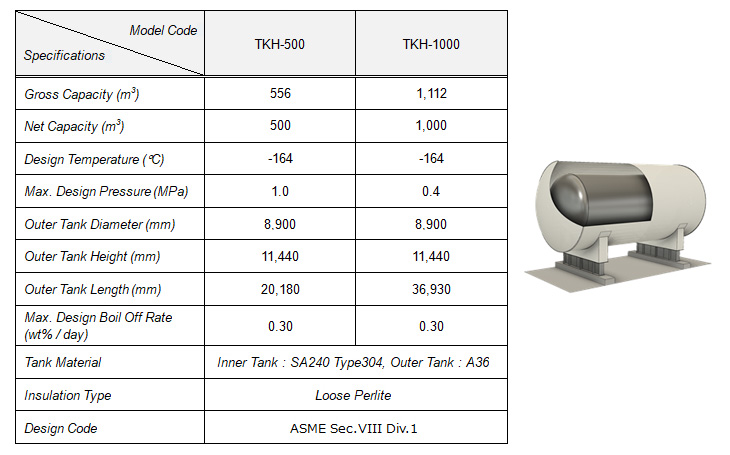

Line-up of Standardized Horizontal Tanks

We can also respond to made-to-order demands with a capacity range from 300 to 1,000 m3.

And Beyond

Modularization of larger LNG Tank

Modularization of large LNG TANK offers a number of advantages conventional construction. The bulk of the fabrication and assembly are performed at Batam plants, which contributes to shorter production lead time and cost reductions.

Cabilities

- Fully fabricated flat bottom cylindrical LNG tank and transport to the site

- Tank system : Single containment tank system

- Tank capacity : 5,000m3 ~ 10,000m3.

- The lead time ranging from storage tank design to mechanical completion : 18 month

The transportation lead time ranging from Batam plant to construction site* : 45 days

* (From Batam plant within 1,000 km)