Plant Business

In 1950, TKK began to apply advanced welding technologies for the manufacturing of welded petroleum tanks cultivated through the manufacture of industrial furnaces. Over the years, we have expanded the operations to build more than 5,700 tanks, including crude oil storage tanks, LNG and LPG cryogenic storage tanks and high-pressure spherical tanks. These tanks are not only safe, economical, and of high quality but are also equipped with superior mechanism, capable of meeting the structural integrity requirements of large-capacity storage in both oil and natural gas producing and consuming countries around the world.

Project Management

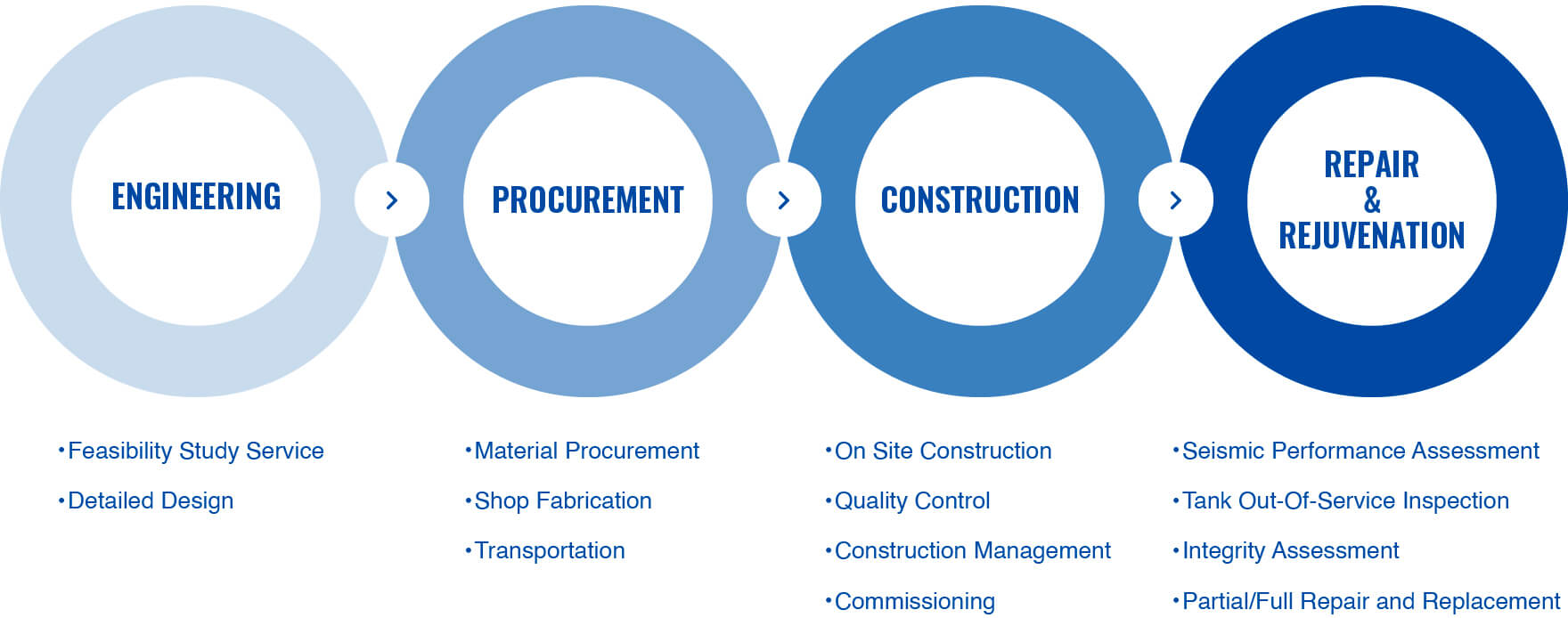

As a specialized storage tank manufacturer, we are capable of handling the full EPC phase, including design, material procurement, construction, repair and rejuvenation of the tank and its auxiliary equipment. We continue to support the world's energy infrastructure in terms of storage with our high project execution capability by challenging new technologies while adopting new construction methods and material.

- Technical capabilities of a specialized tank manufacturer backed by a proven track record of numerous deliveries

- Fabrication plant registered for the JAPEIC Certificate of Welding Management Process under the private product certification by the Japan Electricity Business Act

- Providing integrated services from design, procurement, construction, repair and rejuvenation

Tank Rejuvenation

Life Extension of Aging Tanks

Above-ground storage tanks deteriorate over a long time service. Corrosions, which are the most typical defects, on the steel cause serious incidents. Repairing of the tank at an appropriate time and in a proper way can extend the service life. Tank rejuvenation contributes to the safe operation as well as your facilities life.

Tank Roof

Tank Bottom Plate

Tank Shell

Why TKK ?

As a dedicated storage tank manufacturer with more than 80 years of experience, TKK is committed to providing high value and world-class customer services to our clients. Using our extensive knowledge of the tank manufacturing, TKK provide plant owner with professional services of exceptional value from planning through cleaning, inspection and repair.

Our Services

Investigation and Diagnosis

- Site Investigation by Professional Team

- Tank Diagnosis of Corrosion, Material Thickness, Leakage, Defect etc.

- Propose Optimal Repair Plan

Tank Repair / Replacement Works

- Repair / Replacement of Tank Main Components

- Repair / Replacement of Tank Accessories

Alteration Works

- Tank Roof Alteration for Floating Roof Tank

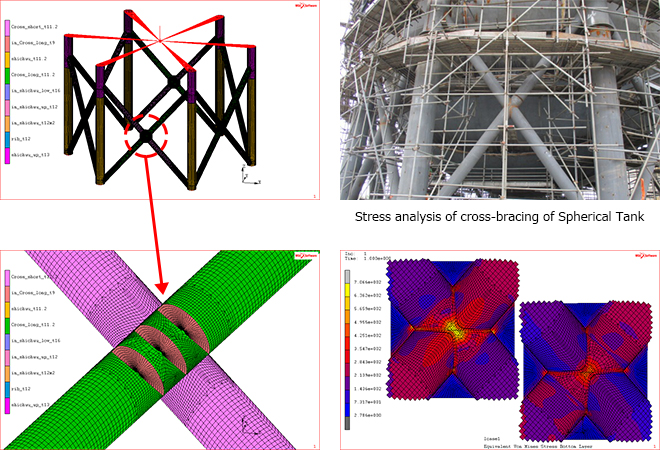

- Reinforcement of Column Bracing for Spherical Tank

Other Works

-

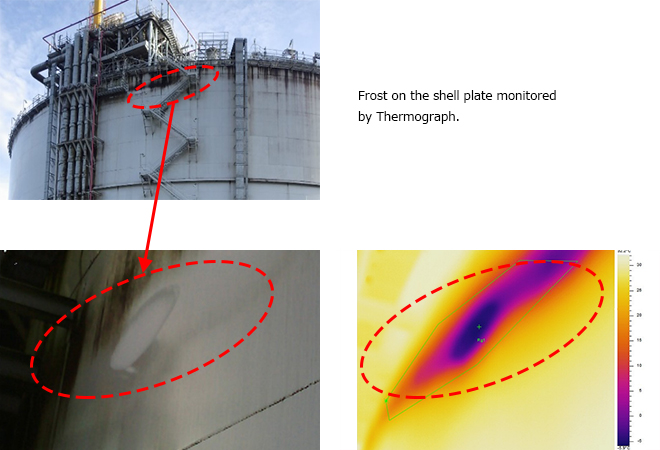

Perlite Topping Up for Low Temperature Double Wall Tank

After years in service, local settlement of the Perlite reduces the insulation efficiency, and causes cold spots on the outer surface of the tank.

TKK can offer the perlite topping-up service on live tanks with proven methodology.

Rejuvenation Method

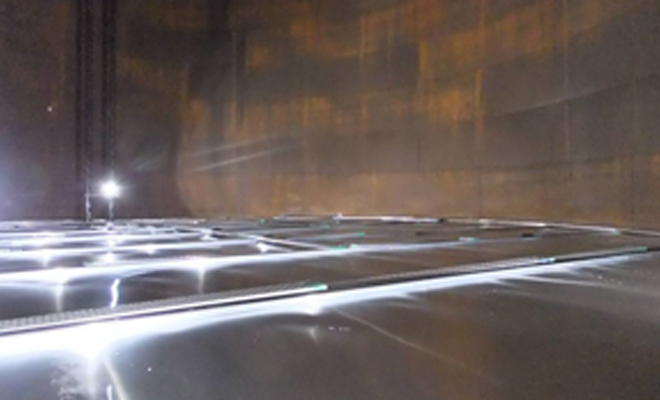

Replacement of Bottom Plates

TKK can propose optimum solutions for the replacement of annular and bottom plates following detailed inspections using a variety of jack-up techniques.

- Full Jack-up Method

- Use of special jacking systems ensures the tank repair to be completed in a safe and efficient manner.

- Enable the foundation repair and the bottom plate replacement to be executed at a time.

- Local Jack-up Method

- Suitable for the partial replacement of bottom plate.

- Can be adopted when the extent of repair is limited and so is the given time window.

- TKK-Wedge Method

- A non-jacking technique to replace the tank bottom plate by supporting the tank with support pieces and simple jigs only.

- Simplify the entire repair process and therefore reduce the work time and safety risks.

Lifting Tank with Jacks

Annular and Bottom Plates Replacement

Full Jack-up for Double Wall Tank

Replacement of Floating Roofs

TKK can offer services for a complete replacement of any type of floating roof in accordance with the latest Codes and Standards.

Tank Roof Alteration

TKK can modify tank roof as follows.

- Open Top Floating Roof→Covered Floating Roof

- Single Deck Floating Roof→Double Deck Floating Roof

- Steel Floating Roof→Aluminum Floating Roof

Steel Floating Roof → Aluminum Floating Roof

Supply and Replacement of Tank Accessories

TKK have been providing and replacing tank spare parts such as sealing material, drain pipe, heater cable, and flange. Furthermore, TKK can propose the alternative equipment with technical endorsement instead of the original, e.g. the latest model, more economical product.

Floating Roof Seal Replacement

Floating Roof Drain System Replacement

Products

Manufacturing Plants

About Procurement

TKK is always willing to take up offers from candidate vendors to supply materials, parts, equipment and service around the world. In selecting procurement sources we place importance on a fair and open process. We focus not only on customer satisfaction but also on coexistence and co-prosperity with partner companies. Please see the list of equipments, materials and services we procure, for your prospective cooperation with us.